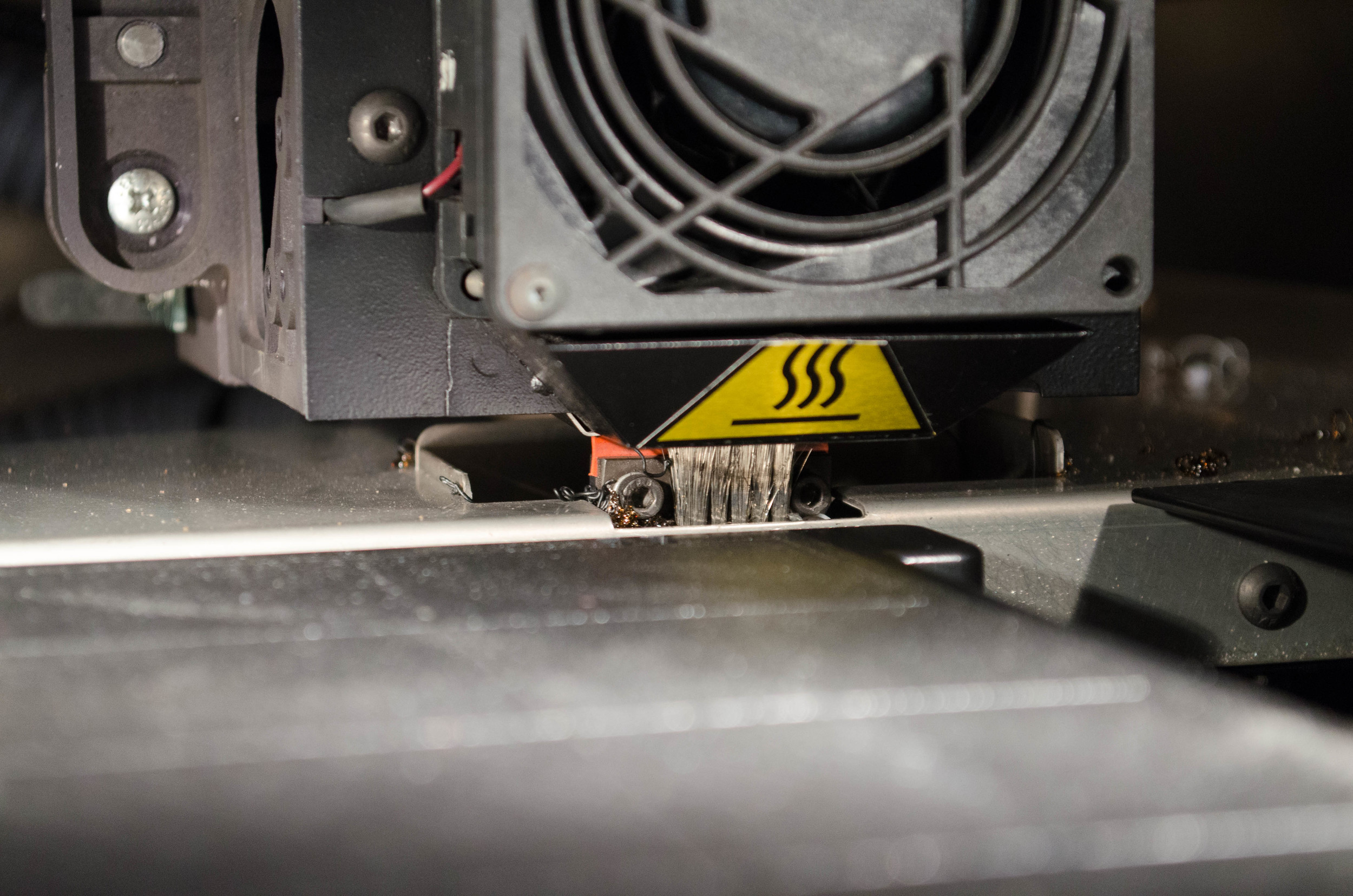

We use Fused Deposition Modeling (FDM) to quickly deliver functional plastic prototypes. In its simplest form, FDM is similar to a hot melt glue gun, precisely depositing material cross section by cross section. As the model is built up, the cross sections fuse together to form a solid prototype.

For more information, Wikipedia has a great description of FDM.

Advantages of FDM

- Fast turnaround - parts can often be printed overnight and shipped the next day.

- Inexpensive when compared to conventional removal processes.

- You can have several design iterations in a compressed timeline.

Our FDM Process

- ABS Plastic - a very common consumer plastic.

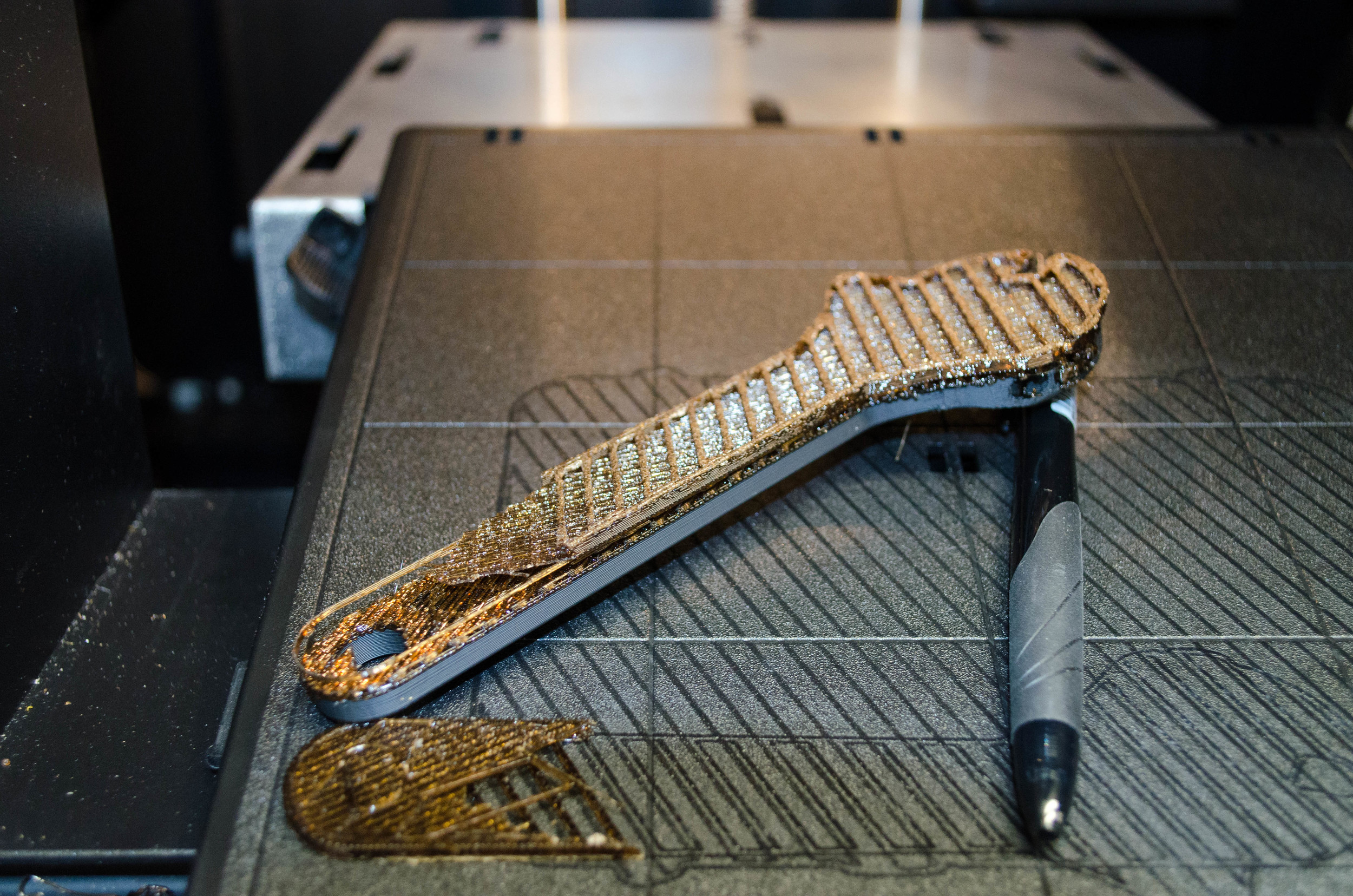

- 0.010" or 0.013" layer resolution.

- Several colors available. See color samples here

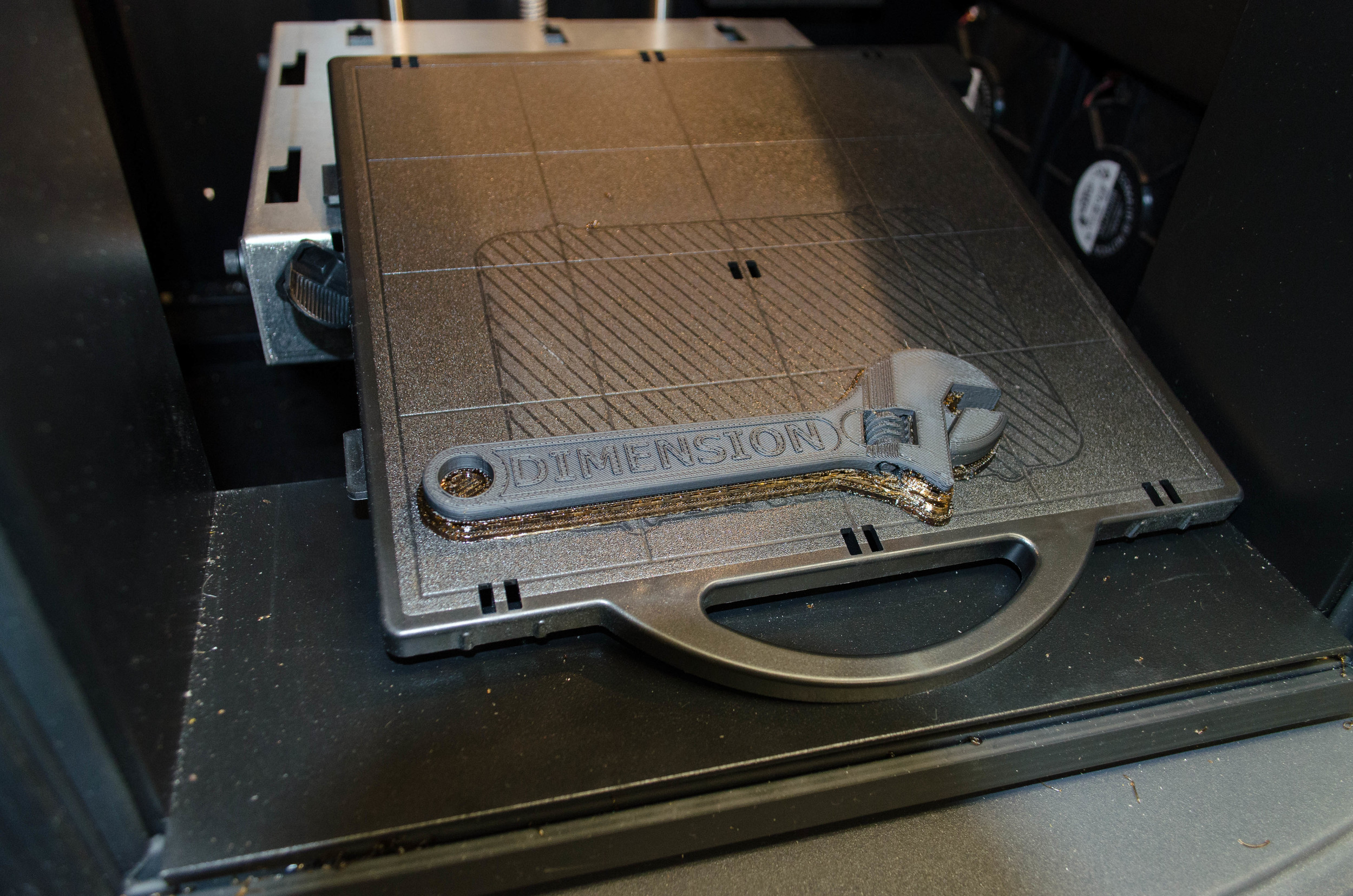

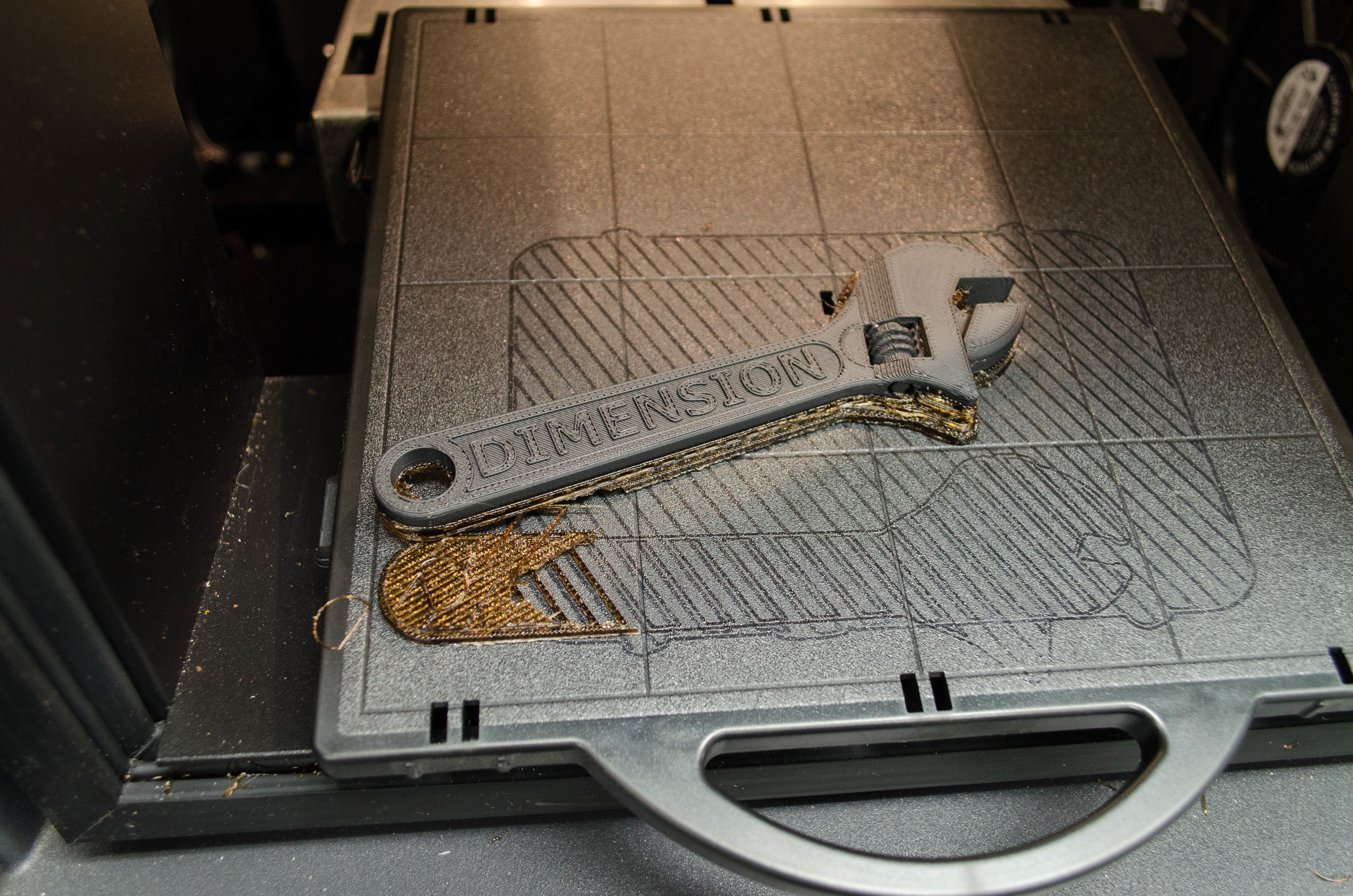

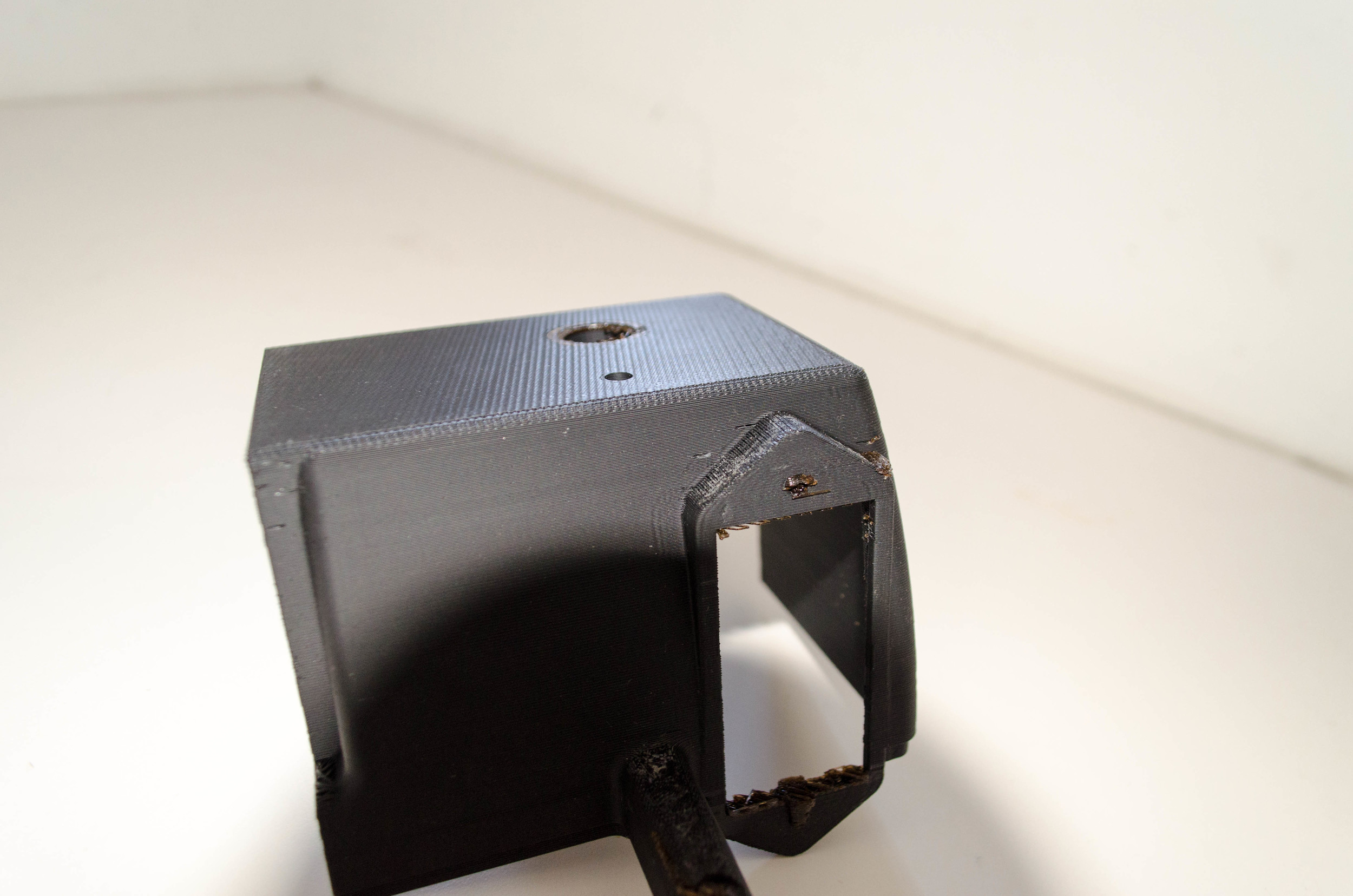

- Soluble support structures - enables functional assemblies to be printed as a single unit. See an example here and in the gallery below.

- Perfect for consumer "form" samples. Test parts can be printed and used in study groups to get feedback on the shape and feel of the part.

- Print size 8" x 8" x 12". Larger parts can be printed, but require assembly after printing.

How Does it Work

Sketch or draft your design. CAD files are great, but we can work with simple sketches too.

Send us your Files. Scan your sketches or simply send us your CAD.

We'll evaluate your design for print-ability. We may offer suggestions to the design to make the printing easier or less expensive.